公司使命

为全球汽车零部件市场提供完美的产品和服务,助合作企业共同成为该行业的领导者,让员工幸福,客户满意,为社会做贡献

我们的企业建立于1992年,特别是致力于生产一系列的汽车产品(球头、拉杆球头拉杆总成、摆臂、吊杆、中心平衡杆、平衡总成、主帮汰、副帮汰、悬架)。

公司位于经济发达的地区--浙江省玉环市东海岸,是一个具有现代科学高科技机械产业的生产基地,具有便利的交通条件。

我们以全新的津力主义通过了IATF16949质量体系认证,我们公司的管理观念是“质量第一,信誉第一,服务第一”。

目前,我们公司能提供8500多种不同的产品,总年产量达到25000000套,公司主要出口到欧洲、美国、东南亚、非洲、中东地区和世界的每个地方。

津力企业的信念是:彼此有益,满足你的需求,我们热烈欢迎国内外客户来商谈合作共同创造美好未来。

占地面积10万平方米

年产能3600万只

产品型号10000种

员工人数1000余人

为全球汽车零部件市场提供完美的产品和服务,助合作企业共同成为该行业的领导者,让员工幸福,客户满意,为社会做贡献

成为全球汽车零部件行业的伟大公司,打造受人尊敬的百年企业

诚信,责任,合作,创新

职业健康安全管理体系认证

测量管理体系认证

浙江省汽摩配行业理事会副会长单位

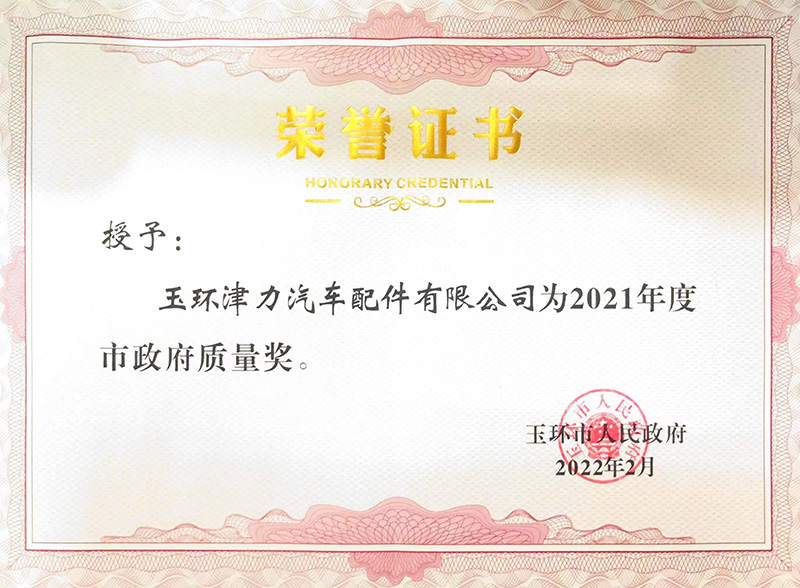

市政府质量奖

市级高新技术研发中心

市二十强工业企业

A级进出口诚信企业